Socorro County Historical Society

Socorro, New Mexico, USA

History

Articles

The west facing rock wall on the Hammel Brewery suffered a major collapse on April 10, 2008. The rock facade gave way and fell into Sixth Street, exposing a large portion of the old adobe load bearing wall. Temporary repairs were made to stabilize the wall from further collapse and support the second story of the building.

SCHS hired a structural engineer to determine the extent of the failure. The inspection revealed the damage was more serious than first thought. Years of hidden water damage had caused an internal “melting” of the adobe wall, causing the rock facade to slowly separate from the adobe until it was free standing. The rock facade began to bow outward until it collapsed under it's own weight. The inspection also revealed the breakdown of the internal load-bearing wall highly compromised support of the second story of the brewery neccessitating major building repairs. Initial repair estimates were about $35,000.

The SCHS Board of Directors felt strongly that the repair must rebuild the load bearing wall and restore the rock facade while preserving the historical integrity and appearance of the building.

The first difficulty encountered was how to rebuild the rock facade – stone masons skilled in that sort of rock work were getting hard to find.

Bruce Burnett, of Accurate Construction Company in Socorro, proposed a novel plan to rebuild the load bearing wall and the rock facade in a cost saving process. The technique is called “slip form rock wall construction” in which a solid concrete load bearing wall and the rock facade are built at the same time. This method rebuilds the wall inside a wooden form about two feet high. When the cement is dry, the form is moved upward for the next two-foot layer. This was repeated until the full height of the load bearing and rock wall was completed.

Repair work began October 2009. Electrical and telephone wiring were relocated, supports for the 2nd story of the building erected, and the old adobe wall removed. Steel rebar installed, the new concrete footing poured, and the load bearing and rock wall constructed. By the end of October, the Hammel Brewery had been properly restored to its 1880s appearance for hopefully another 100 years of service.

Hammel Brewery Wall Collapse, April 10, 2008

The April 10, 2008 wall collapse closed 6th Street for several hours. The fragile load bearing adobe wall clearly exposed. A temporary support was built to support the 2nd story of the building.

Jack hammers were used to remove the old adobe wall and adjoining cement members, beginning October 6, 2009.

Where jack hammers wouldn’t work, good old back breaking work was required.

With adobe wall removed by Oct. 7, upper story is shored with temporary supports.

Building the forms and rebar for the new wall footing.

Pouring the cement for the new footings on Oct. 12.

Building the new concrete footing for supporting the new load bearing wall and rock facade.

With the new footing in place, the "slip form" is built on October 14.

"Slip form" in place and ready to build the first course of the wall.

Photos of the repair, October 2009

New frames using weathered wood for the external doors are built and placed on top of the new concrete footing.

Looking into the “slip form.” The rocks for the external facade are positioned into place.

With rocks in place, form is filled with concrete to build a solid concrete load bearing wall and rock facade together.

The first course of the wall on Oct. 14. The concrete was allowed to dry overnight before moving the form.

On October 15, the slip wall form was raised two feet for the next course of rock and concrete. This was repeated until the full height of the wall was built.

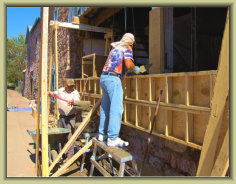

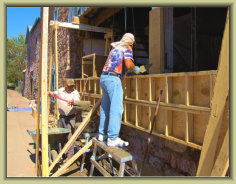

Bruce Burnett positioning facade rocks into place in the form.

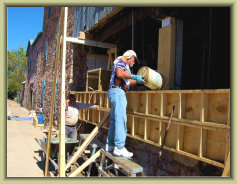

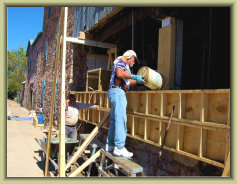

Luis Chavez fills a bucket with cement then lifts the heavy bucket to Bruce.

Bruce pours cement into the slip rock form. By Oct. 19, the wall was about one-half completed.

Slosh & swish the cement around the rocks (there’s probably an engineering term for that).

By October 21, topcourse of the wall had been completed. Finishing and cleaning the rock work followed.

A look at the new load bearing wall from inside of the brewery showing internal stairs to the 2nd floor.

Hammel Brewery and SCHS Museum today

restored to original historic appearance.

(following rock wall repair)

Hammel Brewery, pre-1886

On this page:

HAMMEL BREWERY

2008 WALL COLLAPSE

REPAIR

See also:

Photos by Paul Harden and Jon Spargo